Welcome to ISHWAR STEEL CORPORATION !

Stainless Steel 347

Stainless Steel 347

Type 347 stainless steel has slightly improved corrosion resistance over type 321 stainless steel in strongly oxidizing environments. Type 347 is stabilized with columbium, it is preferable for aqueous and low temperature environments due to its good resistance to intergranular attack. Both 347 and 321 offer good resistance to polythionic acid stress corrosion cracking, encountered in oil refineries. The high temperature oxidation resistance of 347 is similar to that of 304 stainless steel. Useful to 1500°F.

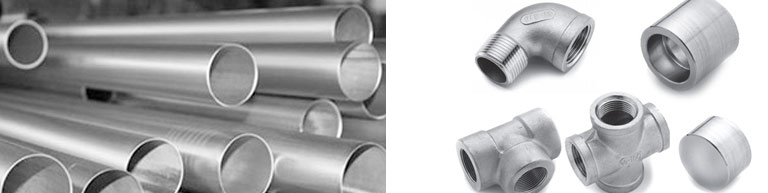

In what form is Stainless Steel 347 available at ISHWAR STEEL CORPORATION?

Chemistry Composition,%

- Bar

- Wire

- Sheet

- Plate

- Forgings

- Pipe

- Flanges

Chemistry Composition,%

| Cr | Ni | Cb + Ta | C | Si | Mn | P | S | Fe | |

|---|---|---|---|---|---|---|---|---|---|

| MIN | 17.0 | 9.0 | Cb 10xc (Cb 8xC) |

0.04 | - | - | - | - | |

| MAX | 19.0 | 13.0 | 1.0 | 0.08 | 0.75 | 2.0 | 0.045 | 0.03 | Balance |

Features

- Good creep strength up to 1500°F

- Maintains good corrosion resistance in applications where the temperature is between 800°F and 1500°F.

- Good resistance to intergranular corrosion in the as welded condition.

What applications might 347 Stainless Steel be used?

- Oil Refineries

- Fluid catalytic cracking units (FCC)

- Hanger rods

- Recuperator tube sheets, shell, supports

- Especially where temperatures exceed 550°F and resistance to sulfidation is needed

- Fired heater tubes

- Distributor trays and thermowells

- Equipment in and around reactors (good resistance to polythionic acid)

Mechanical Properties>

Minimum Specified Properties, ASTM A 240

| Tensile Strength, ksi | 75 |

| 0.2% Yield Strength, ksi | 30 |

| Elongation, % | 40 |

| Hardness Max, Brinell | 201 |

Typical Tensile and Impact Properties

| Temperature, °F | 68 | 400 | 800 | 1000 | 1200 | 1350 | 1500 |

| Ultimate Tensile Strength, ksi | 93.3 | 73.6 | 69.5 | 63.5 | 52.3 | 39.3 | 26.4 |

| 0.2% Yield Strength, ksi | 36.5 | 36.6 | 29.7 | 27.4 | 24.5 | 22.8 | 18.6 |

@2017 Themesflat. All rights reserved.