Welcome to ISHWAR STEEL CORPORATION !

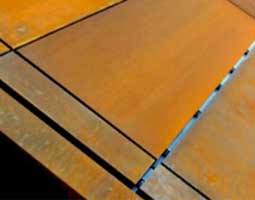

Corten Steels

Corten Steels

ASTM A588 , ASTM A588 , ASTM A588 , ASTM A588 , ASTM A588 EXPORTERS.

A588 Grade C steel plate is for high strength low alloy structural steel with 345Mpa minimum yield point to 100mm thickness.

When propertly exposed to the atmosphere, A588 is suitable for many applications in the bare condition. A588 Grade could be produced in 200mm in our Gangsteel mill.

Supplementary Technology: HIC Test | NACE MR0175 | Z15 | Z25 | Z35 | S2|S3|S5|S6|S8|S18|S30|

Thickness:

6MM to 200Width:

1500mm to 4050mm,Length:

3000mm to 15000mm

|

||||||||||||||||

| Mechanical Properties : Hot Rolled Sheets : | ||||||||||||||||

|

||||||||||||||||

| Mechanical Properties : Cold Rolled Sheets ≤ 3 mm in thickness : | ||||||||||||||||

|

||||||||||||||||

APPLICATIONS : |

||||||||||||||||

| Chimneys, Bridges, Tubular bridges, Facades, Containers, Tanks, Corten Facades |

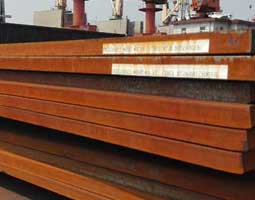

Corten B , Corten B , Corten B , Corten B , Corten B EXPORTERS.

CORTEN B steel”, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. United States Steel Corporation (USS) holds the registered trademark on the name CORTEN B.

The original CORTEN B received the standard designation ASTM A 242 TYPE-II(“COR-TEN B”) from the ASTM International standards group. Newer ASTM grades are A 588 (“CORTEN B”) and A 606 for thin sheet. All alloys are in common production and use.

The material forms its own protective layer when exposed to atmospheric elements. Essentially, the top layer corrodes which then protects the steel beneath it. The natural finish does not normally require any form of maintenance such as painting, which makes the material a highly cost effective alternative to other structural steels.

Chemical Properties

| C | Si | Mn | P | S | Cr | Cu | Ni |

| ≤ 19 | 0.30 – 0.65 | 0.80 – 1.25 | ≤ 0.035 | ≤ 0.030 | 0.40 – 0.65 | 025 – 0.40 | ≤0.40 |

Mechanical Properties : Hot Rolled Sheets ≤ 16 :

| Yield Strength(MPa) | Tensile Strength(MPa) | Minimum Elongation A(Lo = 5.65 √So) % |

| 355 | 470 – 630 | 20 |

Corten B , Corten B , Corten B , Corten B , Corten B EXPORTERS.

CORTEN B steel”, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. United States Steel Corporation (USS) holds the registered trademark on the name CORTEN B.

The original CORTEN B received the standard designation ASTM A 242 TYPE-II(“COR-TEN B”) from the ASTM International standards group. Newer ASTM grades are A 588 (“CORTEN B”) and A 606 for thin sheet. All alloys are in common production and use.

The material forms its own protective layer when exposed to atmospheric elements. Essentially, the top layer corrodes which then protects the steel beneath it. The natural finish does not normally require any form of maintenance such as painting, which makes the material a highly cost effective alternative to other structural steels.

Chemical Properties

| C | Si | Mn | P | S | Cr | Cu | Ni |

| ≤ 19 | 0.30 – 0.65 | 0.80 – 1.25 | ≤ 0.035 | ≤ 0.030 | 0.40 – 0.65 | 025 – 0.40 | ≤0.40 |

Mechanical Properties : Hot Rolled Sheets ≤ 16 :

| Yield Strength(MPa) | Tensile Strength(MPa) | Minimum Elongation A(Lo = 5.65 √So) % |

| 355 | 470 – 630 | 20 |

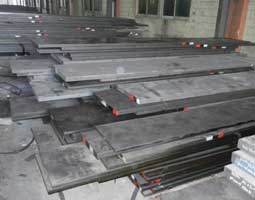

Hardox 450 Plate , Hardox 450 Plate , Hardox 450 Plate , Hardox 450 Plate , Hardox 450 Plate EXPORTERS.

Hardox 450 is an abrasion resistant plate with a hardness of 450 HBW, intended for applications where demands are imposed on abrasion resistance in combination with good cold bending properties. Hardox 450 offers very good weld ability.

Applications:

Crushers, sieves, feeders, measuring pockets, skips, cutting edges, conveyors, buckets, knives, gears, sprockets, dump trucks, loaders, industrial trucks, lorries, bulldozers, excavators, slurry pipe systems, screw conveyors, presses etc.

Hardness HBW :

425-475Dimensions :

•Plate thicknesses of 3 mm-130 mm

•Width: Up to 3000 mm

•Length Up to 12000 mm

Heat Treatment :

Hardox 450 has obtained its mechanical properties by quenching and when necessary by means of and Fabrication subsequent tempering. The properties of the delivery condition can not be retained after exposure to service or preheating\ temperatures in excess of 250oC (480o F).

Hardox 450 is not intended for further heat treatment For information concerning welding and fabrication please send us

Appropriate health and safety precautions must be taken when welding, cutting, grinding or otherwise working on the product. Grinding, especially of primer coated plates, may produce dust with high particle concentration.