Welcome to ISHWAR STEEL CORPORATION !

Inconel 625

Inconel 625

ISHWAR STEEL CORPORATION is a renowned manufacturer in India and oldest SUPPLIER of inconel pipe Specialty pipe like inconel 600 pipe are what make us stand out from the crowd. We are the only company in INDIA with over 200 tons stock of inconel pipe.We at ISHWAR STEEL CORPORATION we maintain various sizes in STOCK of inconel 625 pipe

Alloy 625 is a nickel-chromium alloy designed for use from cryogenic to elevated temperatures in the range of 2000 deg F(1093 deg C). The high nickel content of the alloy enables it to retain considerable resistance under reducing conditions and makes it resistant to corrosion by a number of organic and inorganic compounds. The nickel content gives it excellent resistance to chloride-ion stress-corrosion cracking and also provides excellent resistance to alkaline solutions.

Due to its low carbon content and stabilising heat treatment, alloy 625 shows little tendency to sensitisation even after 50 hours at temperatures in the range 650-900°C (1200-1650°F).The alloy is supplied in the soft-annealed condition for applications involving wet corrosion, and is approved by TUV for pressure vessels in the temperature range -196-450°C (-321-840°F).For high-temperature applications a modified version of alloy 625 is available on request.The mechanical properties of alloy 625 can be increased by age-hardening

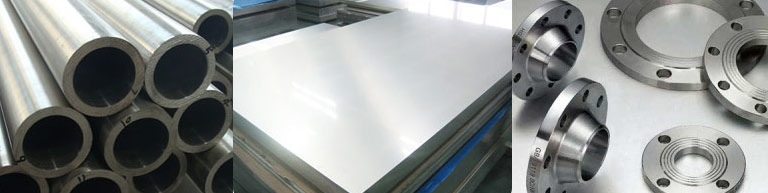

In what form is Inconel 625 Available at ISHWAR STEEL CORPORATION

- Sheet

- Plate

- Bar

- Pipe & Tube (welded & seamless)

- Flanges

- Wire

What are the characteristics of Inconel 625?

- High creep-rupture strength

- Oxidation resistant to 1800° F

- Seawater pitting and crevice corrosion resistant

- Immune to chloride ion stress corrosion cracking

- Non-magnetic

Chemical Composition, %

| Cr | Ni | Mo | Co + Nb | Ta | Al | Ti | C |

|---|---|---|---|---|---|---|---|

| 20.00-30.00 | Remainder | 8.0-10.0 | 1.0 max | 3.15-4.15 | .40 max | .40 max | .10 max |

| Fe | Mn | Si | P | S | |||

|---|---|---|---|---|---|---|---|

| 5.0 max | .50 max | .50 max | .015 max | .015 max |

Fabrication with Inconel 625

Alloy 625 has excellent forming and welding characteristics. It may be forged or hot worked providing temperature is maintained in the range of about 1800-2150° F. Ideally, to control grain size, finish hot working operations should be performed at the lower end of the temperature range. Because of its good ductility, alloy 625 is also readily formed by cold working. However, the alloy does work-harden rapidly so intermediate annealing treatments may be needed for complex component forming operations. In order to restore the best balance of properties, all hot or cold worked parts should be annealed and rapidly cooled. This nickel alloy can be welded by both manual and automatic welding methods, including gas tungsten arc, gas metal arc, electron beam and resistance welding. It exhibits good restraint welding characteristics.

ASTM Specifications

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting | Wire |

|---|---|---|---|---|---|---|---|---|

| B444 | B705 | B444 | B704 | B443 | B446 | - | - | - |

Mechanical Properties

Representative Tensile Properties, bar, 1800° F anneal

| Temp° F | Tensile (psi) | .2% Yield (psi) | Elongation in 2 “ (%) |

|---|---|---|---|

| 70 | 144,000 | 84,000 | 44 |

| 400 | 134,000 | 66,000 | 45 |

| 600 | 132,000 | 63,000 | 42.5 |

| 800 | 131,500 | 61,000 | 45 |

| 1000 | 130,000 | 60,500 | 48 |

| 1200 | 119,000 | 60,000 | 34 |

| 1400 | 78,000 | 58,500 | 59 |

| 1600 | 40,000 | 39,000 | 117 |

@2017 Themesflat. All rights reserved.